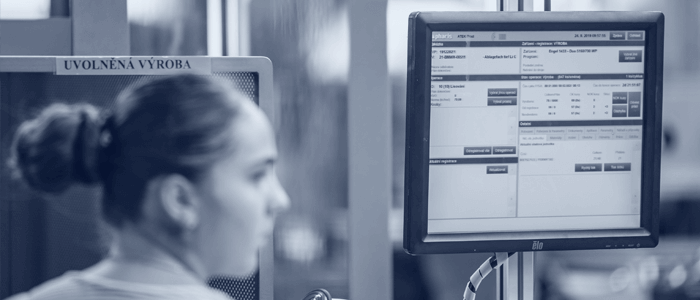

MES PHARIS can effectively measure and evaluate production performance. It is a tool that provides undistorted data for objective production evaluation and operational strategic management.

MES PHARIS gives you an effective tool for evaluation of your production:

The most common indicators for measuring production performance include in particular:

With the help of MES PHARIS, you can detect critical points and analyze the root causes.

Production equipment efficiency is the key indicator for production performance tracking.

The OEE indicator discovers performance and utilization gaps in production.

For equipment efficiency evaluation, MES PHARIS offers a wide range of indicators, e.g.:

MES PHARIS includes work calendars for equipment and staff availability in shifts. Staff availability not only affects production evaluation, but also constrains production planning and scheduling.

The production timeline is one of the important tools that demonstrably improves the OEE.

It is a dynamic graphic tool that visually compares the actual machine time with the clocked times of the operators and setters.

It displays any discrepancy between the machine runtime and the information entered via the production terminal.

For the group of machines selected by the user, the system displays two lines for each machine:

MES PHARIS has an integrated application for user defined reports, which includes a preset of commonly used reports, as well as the ones created by the user.

Typical reports include, for example:

We will be happy to help you with the digitization of processes and production management in accordance with IATF 16949. This way you will get an online overview of production orders in progress, modern paperless production, precise documents for customer audits, traceability, and all this in accordance with the principles of Industry 4.0. This competitive advantage will also help you to get new projects. Get rid of chaos in records, stress before audits and use a professional and long-term proven solution.