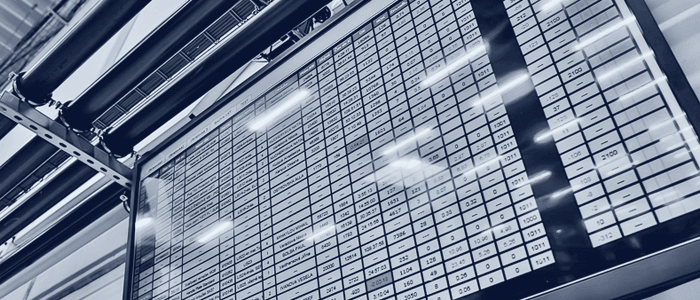

Production visualization finds its application mainly on large screens located directly in production facilities. They are used for quick and clear overview of production. They display current state of production equipment and work in progress.

Visualization provides timely and clear information to workers moving in the production hall without having to log in to MES PHARIS.

Production Visualization module also includes a user editor, which allows customers to create the appearance of screens with any content. Dynamic objects on visualization screen also offer support for workflow management, especially in area of quality, internal logistics, or maintenance.

Visualization screens in production halls typically display:

The production visualization module closely uses the Alarms and Escalation System and KPI – key production indicators and reports.

The visualization screen is represented by a dynamic web page and is therefore accessible from any computer or mobile phone.

Large screens are placed mainly in production halls, assembly rooms, control rooms, workshops, etc.

MES PHARIS offers the possibility of user definition and editing the appearance of the visualization screens.

A number of predefined objects and their attributes are available in the integrated screen editor, which display current data from the system database.

MES PHARIS supports the possibility of creating any number and types of screens, which are chosen according to the context of the location of the large screen in production.

Through the visualization screens, it is easy to implement the Andon system to comply with the principles of lean manufacturing.

For effective use, we recommend connecting the Andon system to the Alarms and Notification module.

We will be happy to help you with the digitization of processes and production management in accordance with IATF 16949. This way you will get an online overview of production orders in progress, modern paperless production, precise documents for customer audits, traceability, and all this in accordance with the principles of Industry 4.0. This competitive advantage will also help you to get new projects. Get rid of chaos in records, stress before audits and use a professional and long-term proven solution.